Our Factory is Focused on Details

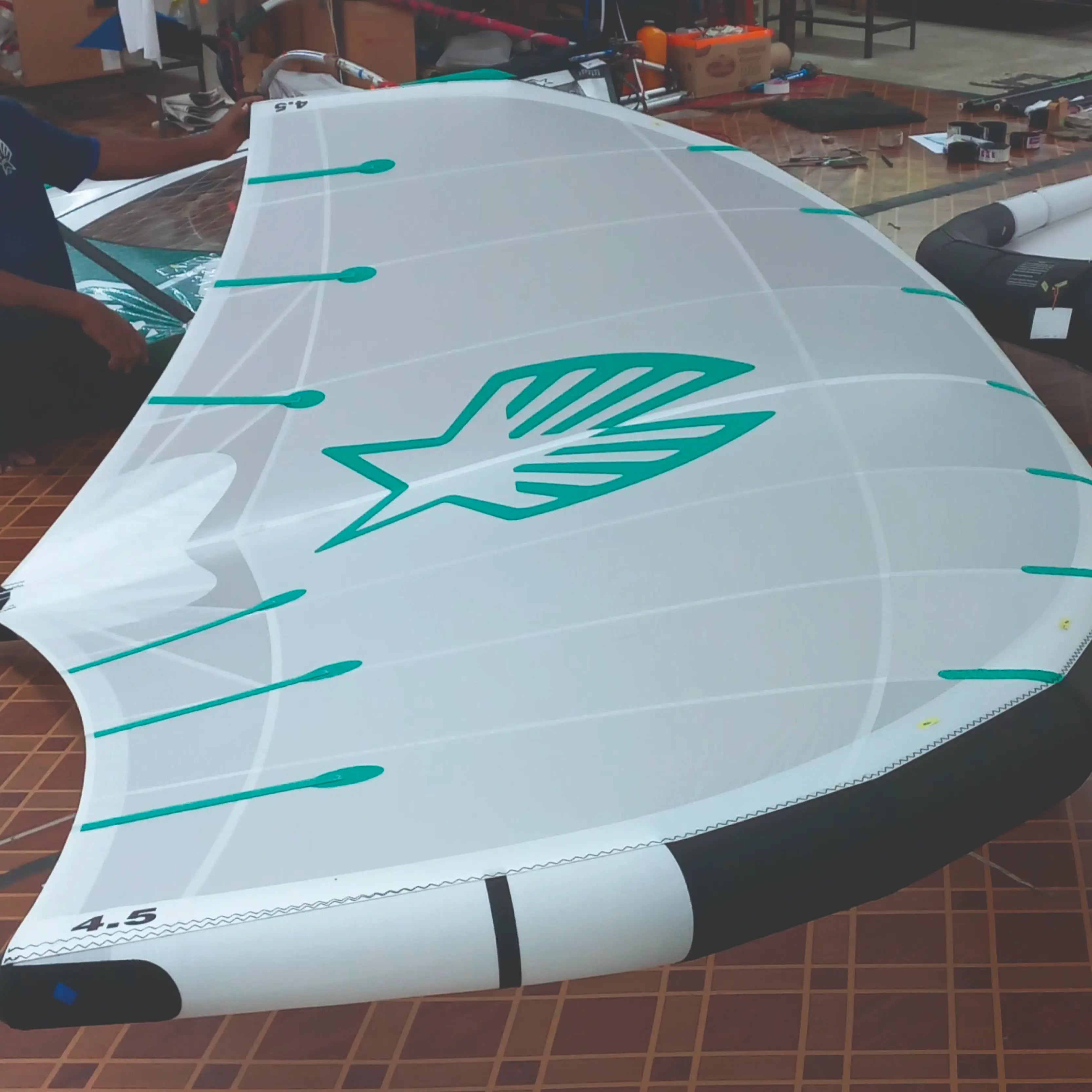

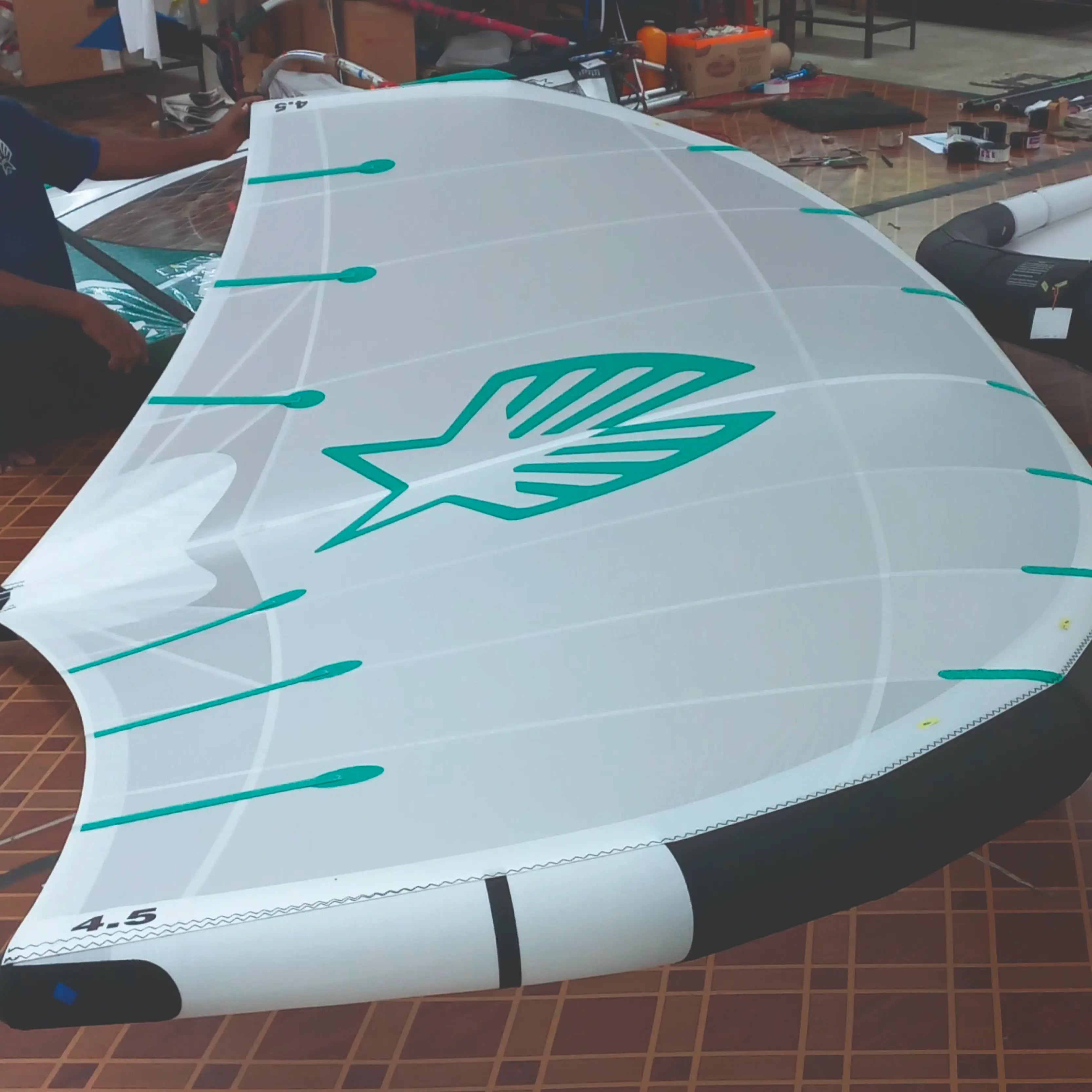

Production is all about minimizing and catching mistakes. Each wing gets inflated, measured and then is thoroughly inspected. After that, we leave it inflated overnight just to make sure the bladders don't leak.

We spend a lot of time during production making sure the left and right sides are identical. This means having perfect threadline alignment on the leading edge segments, as well as the canopy panels.

Production is all about minimizing and catching mistakes. Each wing gets inflated, measured and then is thoroughly inspected. After that, we leave it inflated overnight just to make sure the bladders don't leak.

We spend a lot of time during production making sure the left and right sides are identical. This means having perfect threadline alignment on the leading edge segments, as well as the canopy panels.

40 Years of Making Windsurfing Sails Goes into Every Wing

Making wings share a lot of similarities to making windsurfing sails.

- Seams must be precise. Our seam tolerance is 0.25mm.

- Panel tensions must be the same on both sides, otherwise you get wrinkles in your seams.

- Panels must be cut ultra precise, otherwise the symmetry can be off.

- All seams must be glued and sewn for maximum seam hold.

- Reinforcements must be big enough to distribute tensions in order to have a long lasting wing.

- Don't rush and get it right.

For a detailed explanation of how a wingfoil wing is designed and built, read our in-depth article.

It's All About the People

Quality comes from having people that care about getting it right.

We Are Family

We measure our success by the happiness of our team. Our factory is based on the respect and compassion of our fellow workers. We treat everyone the way we would want to be treated. We listen to concerns and try to help our staff wherever and whenever we can.

Ezzy Foundation

Education has the power to solve all of the world’s main problems.

A portion of every sail made in the Ezzy factory goes into the Ezzy Foundation Fund from which money will go to purchase school supplies for children of our employees at Ezzy Sails Lanka.