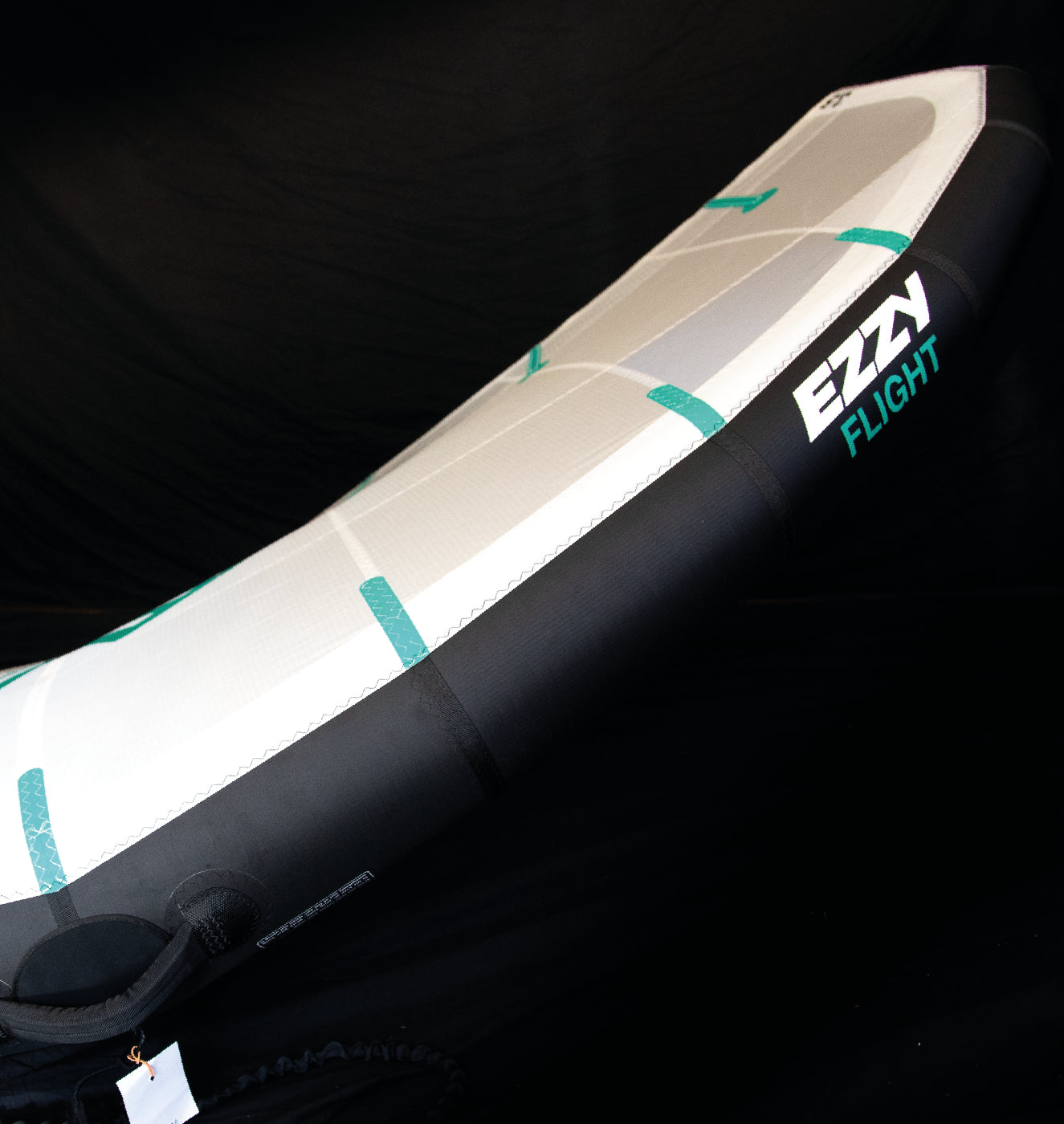

Performance and Durability

Our v.2 wing has undergone major changes from our v.1.

• A deeper, more draft forward profile improves stability, upwind pointing and low-end power.

• New W-80, warp orientated cloth used on the trailing edge has 40% less stretch than standard canopy fabrics. This prevents trailing edge flutter and greatly increases the longevity of the wing.

• New, W-50 canopy cloth is a lighter version of the W-80 and is used for the main canopy.

• We invented a system we call the “Strut Loop” to improve the strut-to-canopy connection. The Strut Loop locks the canopy to the strut, which improves stability and overall performance.

• New radial seams reduce stretch and flutter by aligning the load paths at the back of the canopy.

• The trailing edge stabilizers are aligned perpendicular to the trailing edge to better resist flutter.

• New light weight radial canopy patch aligns the load at the end of the strut to prevent stretch.

• Lower leading edge handle improves flagging and makes the wing neutral for wave riding.

• Available soon: a retrofittable full boom. This will allow you to swap out the two handles for a single boom.

The Ezzy Flight v.2 wing is for all levels of wingers. It is our goal to make a high performance, all around wing that will outlive other wings.

Sizes & Specs.

Windrange (Kts)

Wingspan (CM)

PSI Leading Edge/ PSI Strut

22-45

225

8/8

20-36

249

8/8

17-34

276

8/8

15-30

291

8/8

13-27

307

8/8

12-26

327

8/8

10-24

344

8/8

9-23

360

8/8

WE'VE DONE OUR HOMEWORK WHEN IT COMES TO MATERIALS

Lightweight, ergonomic handles match your wrist angle so you are able to relax your arms.

Our low stretch dacron is the best in its class in terms of stretch, firmness and durability.

New W-80, warp orientated cloth used on the trailing edge has 40% less stretch than standard canopy fabrics.

This prevents trailing edge flutter and greatly increases the longevity of the wing.

New, W-50 canopy cloth is a lighter version

of the W-80 and is used for the main canopy.

Surgical grade, 100 micron bladder material is the best in the industry.

Separate leading edge and strut valves allows for different air pressures between the strut and leading edge. This produces a stiffer feeling wing and it also gives you the added security that you will always be able to make it back to the beach in case of a mishap.

WE HATE STUFF THAT BREAKS

Durability and workmanship are hard wired into our DNA and apply to every aspect of our wings.

Comfortable Handles

Lightweight and ergonomic.

Materials From the World's Top Sailcloth Producers

We only use materials that have a proven track record.

Attention to Details

All panels and reinforcements are glued and sewn for maximum bond strength.

Valves

Separate leading edge and strut valves provide superior stiffness, as well as extra security and faster deflation.

High tension canopy

Our performance gains come from our tight canopies.

THE FLIGHT

WE ARE ON A MISSION...

Our Mission Statement:

- To make the best wing in the world.

- To provide a safe and happy work environment for our workers in Sri Lanka.

- To provide the best customer support.

- To make a profit on every wing sold.

- To treat everyone with respect.

- To enjoy our journey.

30 years of experience

We have been developing and testing sailcloth for over 30 years.

We encompass numerous ways to improve processes and products to make them more efficient from an environmental and sustainable standpoint.

Every one of these approaches depends on viewing possible impacts in space and time: improving the general product quality for a longer product live circle, reducing print & paint for less pollution, educating workers and optimising processes to reduce waste, etc.

...TO MAKE THE BEST WINGS IN THE WORLD

FAQ

Why should I buy an Ezzy wing?

When you buy an Ezzy wing, you are getting our 40+ years of windsurf sail design knowledge, as well as our 30+ years of manufacturing experience.

And, since we own our own factory, we are able to devote an inordinate amount of time getting things perfect on the wing.

Most wings are made in factories that produce many wing brands and these factories won't do the extra quality steps that we insist on for our wings.

What rider level are you targeting for your wings?

The Flight is a crossover wing that suits any rider level. It's stiff frame construction and unprecedented balance makes it the wing of choice for all riders, beginner to advanced.

What conditions is the Ezzy Flight Wing designed for?

The Flight is a true crossover wing that works outstandingly in all conditions.

- flatwater

- waves

- highwind

- lightwind

What will I feel is the difference between an Ezzy Flight Wing and other brands?

This of course depends on what brand you are comparing to, but most people find the Flight is more stable, goes upwind better, pumps better and is quieter.